You can also request a free quote. Product recall indicates that there is some quality issue in the product.

Inspection Plan Qaqc Systems Qa Qc Construction

The cost of any activity designed to appraise test or check for defective products.

. 11-03 Eacker Companys quality cost report is to be based on the following data. C Test and inspection of incoming materials. Internal failure costs are those that would exist before sorting out and removal of the defects prior to shipment.

Final product testing and inspection. Costs of inspecting and testing products are classified as a. A product quality inspection is a procedure that involves checking the various attributes of a product and testing it to ensure that it meets pre-specified standards.

Supplier scrap and rework. C Supplies used in testing and inspection. Quality engineering 72000 Net cost of spoilage 70000 Re-entering data because of keying errors 88000 Test and inspection of incoming materials 68000 Test and inspection of in-process goods 97000 Technical support provided to suppliers 83000 Maintenance of test.

Appraisal costs are the costs incurred for inspection of products and are termed as bad costs which verify whether an activity was done properly or not. Net cost of scrap. Accounting questions and answers.

The cost of testing incoming materials received from suppliers would be classified as a n. Costs of inspecting and testing products are classified as a. Depreciation of test equipment.

Test and inspection of incoming materialsin-process goods final product testing and inspection supplies used in testing and inspection supervision of testing and inspection depreciation of test equipment maintenance of test equipment field testing. Scrap and rework costs due to nonconforming product received from suppliersThis includes the costs to the buyer of resolving the supplier quality problems. Companies pay appraisal costs as part of the quality control process to ensure that their products and services meet customer.

The factorys quality control team a buyer or a third-party inspection company like Insight Quality Services can conduct this inspection. The net loss in labor and materials resulting from defective products. A Debugging software errors.

B Quality training. Categories of quality costs. B Repairs and replacements beyond the warranty period.

Inspection and testing procedures are followed before during and after the product manufacturing for ensuring that the level of quality of the. Costs of inspecting and testing products are. The cost of completing 100 inspection to sort defective.

It can be classified as an external failure cost on quality cost report. Many experienced importers send an. The cost of quality training would be classified as a n.

Costs of inspecting and testing products are classified as a external failure costs b appraisal costs c internal failure costs d prevention costs. Which of the following would be classified as a prevention cost on a quality cost report. Internal failure cost on a quality cost report super Vision of testing and inspection activities because these activities are the part of the product so this is considered an internal failure cost.

They just segregate bad products from good but do not prevent the errors. In addition to testing services we provide consultation services create product-specific test plans and fabricate custom fixtures. D Cost of field servicing and handling.

Terms in this set 34 inspection of products would be classified as a n. Hence Option B is the correct answer. Which of the following would be classified as an external failure cost on a quality cost report.

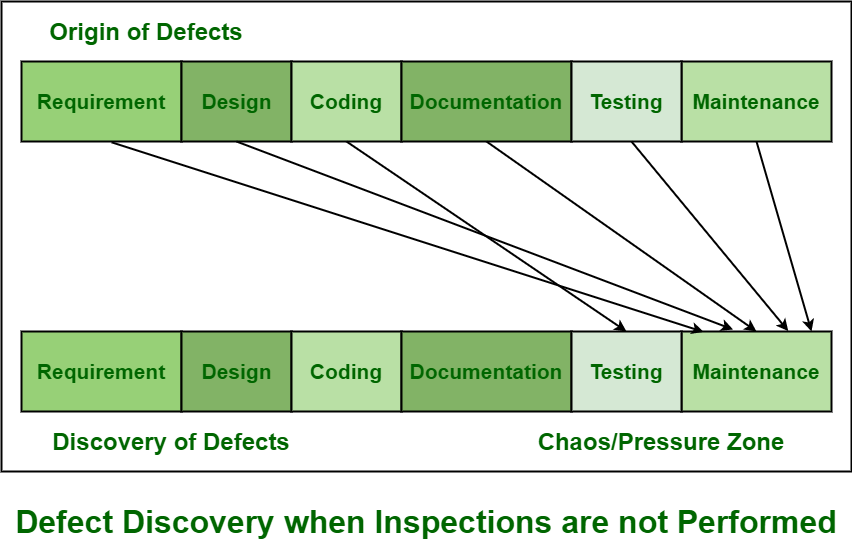

Internal failure cost is related to internet product or any product developed in an organization to check the product. Inspection and testing are indispensable tools of manufacturing process since they help to control quality reduce manufacturing costs reduce rejection losses and assign causes for the production of defective product. Chapter 2 Cost Terms Concepts and Classifications 53.

Costs of inspecting and testing products are classified as a. The cost analyzing nonconforming goods or services to determine the root causes. D Re-entering data because of keying errors.

Appraisal costs are a specific category of quality control costs. Supervision of testing and inspection activities. These are the costs of coping with errors discovered during development and testing and would be comprised of.

A Depreciation of test equipment.

Difference Between Software Inspection And Software Testing Geeksforgeeks

0 Comments